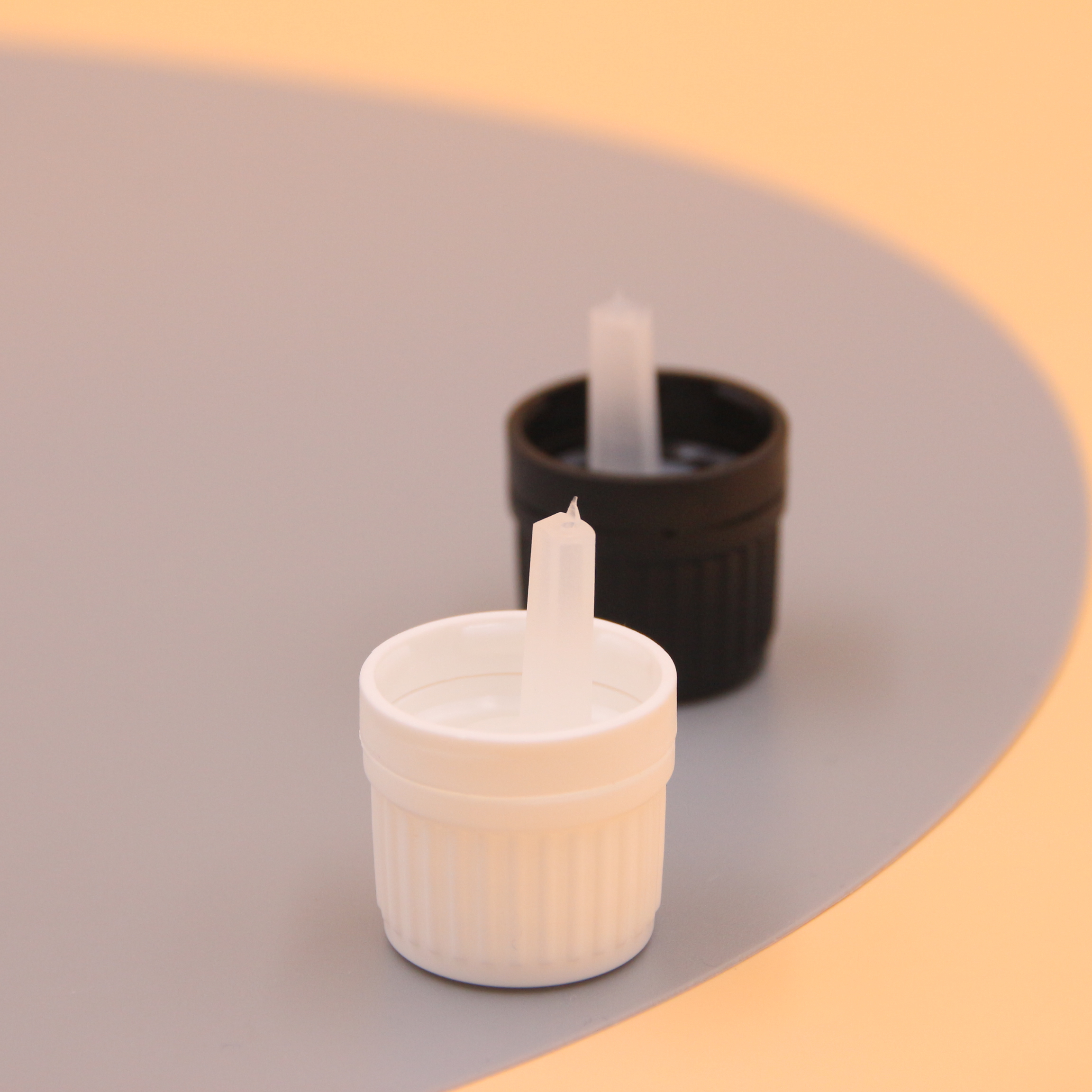

wholesales European style 18/410 black white color plastic tamper proof cap for essential oil bottle with insert

Material Analysis

In terms of material, it is generally divided into PP and PE. PP material: It is mostly used for gas beverage bottle cap gaskets and caps. It is heat-resistant and does not deform, has high surface strength and good chemical stability. The disadvantage is that it has poor toughness and is easy to become brittle under low temperature conditions. Wear-resistant. Bottle caps of this material are mostly used for fruit wine and carbonated beverage bottle cap packaging. PE material: mostly used for hot-fill bottle caps and aseptic cold-fill bottle caps. This material is non-toxic, has good toughness and impact resistance, is also easy to form a film, is resistant to high and low temperatures, and has better environmental stress cracking performance. Well, the disadvantage is that the molding shrinkage is large and the deformation is severe. Many vegetable oils on the market, such as sesame oil in glass bottles, are mostly made of this material. Plastic bottle caps are generally divided into gasket type and inner plug type. The production process is divided into compression molding and injection molding. Most of the sizes are: 28 teeth, 30 teeth, 38 teeth, 44 teeth, 48 teeth, etc.

The number of teeth is divided into multiples of 9 and 12. The anti-theft ring is divided into: 8 buckles, 12 buckles and so on.

Most of the structures are: separate connection type (also called bridge type) and one-time molding type. Uses are generally divided into: gas bottle caps, heat-resistant bottle caps and sterile bottle caps. Due to the low cost of plastic materials and the combination of the advantages of many materials, it is also welcomed by packaging container material factories to a certain extent. However, due to the change in its structure and performance is not very clear, it still needs to be considered in the application of some food packaging fields. However, with the development of science and technology, the application of plastic lids in the field of food packaging will become more and more extensive.

Product Specification

| tem name | wholesales European style 18/410 black white color plastic tamper proof cap for essential oil bottle with insert |

|

Description |

1. glass pipette dropper |

| 2. Closure type: Normal, tamper evident, CRC, tamper evident and CRC, childproof, press and turn cap. | |

| 3. Material: Plastic, Glass, Alu. | |

| 4. sizes available: 13/410, 13/415, 15/415, 18/410, 18/415, 20/400, 20/410, 22/400, 22/410, 24/410, 28/410. | |

| 5. glass pipette dropper color as you like, bulb color as you like. | |

| 6. MOQ: 10,000 pcs glass pipette dropper | |

| 7. Shape of pipettes as you like. (Customized shape can be made according to your request.) | |

| 8. Material of bulb (teat): rubber, silicone gel, pvc, TPE, etc. | |

| 9. Feature: all common sizes are available, with or without aluminum, easy to open. | |

| 10. glass pipette dropper samples free, freight collects. | |

| Others | 1. Usually used for essential oil bottle, lotion bottle, serum bottle, easy to use. |

| 2. Pipette length according to your request, with or without scale (printing). | |

| Applications | Used for essential oil, lotion, serum, etc. |

| Packing | 3500pcs rubber teat dropper per carton |

| Meas. of carton | 50x 36x 26cm |

| Lead time | 15-25 days. |

| Warranty | One year |

Characteristics

Parking And Delivery

Lead Time

| Quantity(pieces) | 1 - 100000 | >100000 |

| Est. time (days) | 7 | To be negotiated |

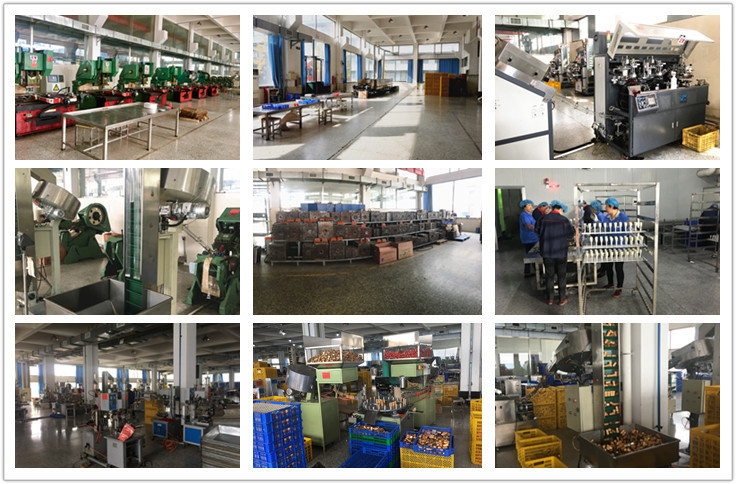

Production environment